MATLAB and Simulink enable engineers to address the growing complexity of modern production equipment and the demand for higher flexibility.

Industrial Automation and Machinery engineers use Model-Based Design in MATLAB and Simulink to:

- Design and test machine controls and supervisory logic

- Run automatic tests on equipment functions

- Design artificial intelligence (AI) algorithms for predictive maintenance and operations optimization

- Generate real-time code (C/C++, IEC 61131-3) for industrial controllers and PLCs

Digital Twin

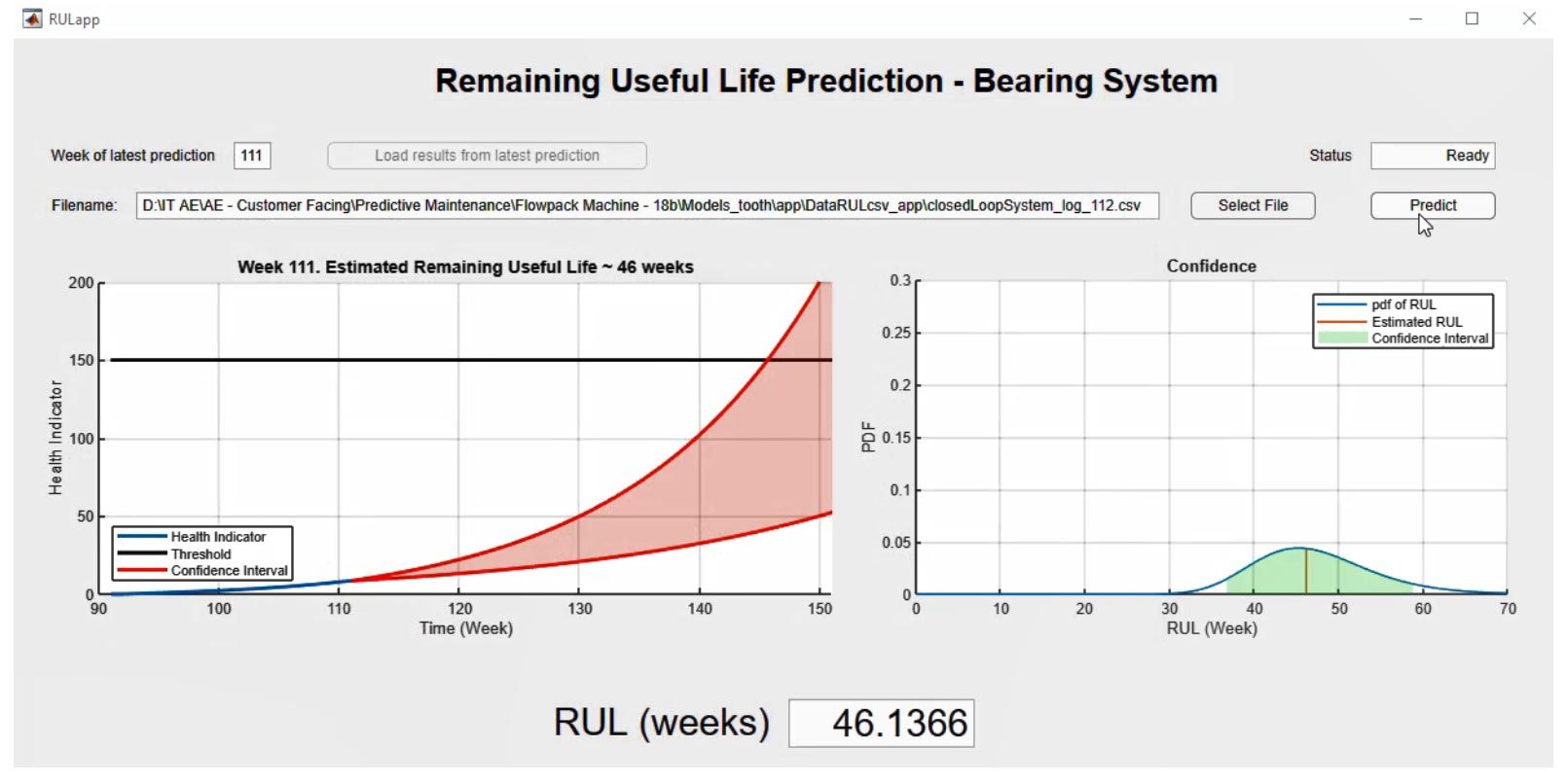

With MATLAB and Simulink, engineers can define models using physics-based, multi-domain modeling tools, as well as data from their assets. Both data-driven and physics-based models can be tuned with real-world data from the operating asset to act as a digital twin. Engineers can use these digital twins for prediction, what-if simulations, anomaly detection, fault isolation, and more.

Using MATLAB and Simulink, engineers can implement a digital twin wherever it makes sense for their application (edge smart devices, PLCs, or industrial controllers, or in the system’s IT infrastructure).

Customer Success

- Digital Twin of a Drilling Rig: Using Simulink to Predict Rig Performance | MATLAB Oil and Gas Conference 2019 (22:59)

- Tata Steel Saves Energy on Cooling Towers Through Software Algorithms

- Festo Develops Innovative Robotic Arm Using Model-Based Design

- Transpower Ensures Reliability of New Zealand National Grid with Reserve Management Tool

Artificial Intelligence

Using MATLAB and Simulink, engineers can embed AI and data science algorithms in industrial automation applications without being an expert in data science or machine learning. For example, engineers can manage poor quality data by using dedicated apps to label data or train AI models.

Customer Success

- Krones AG Builds Reinforcement Learning–Based Process Control in the Blow Molder Contiloop AI for PET and rPET Bottles

- Mondi Implements Statistics-Based Health Monitoring and Predictive Maintenance with Machine Learning

- Baker Hughes Develops Predictive Maintenance Software Using Data Analytics and Machine Learning

Virtual Commissioning

With MATLAB and Simulink, engineers can use a simulation model of the components, systems, or plants to test and validate their design before implementing it on actual prototyping or production equipment. Virtual commissioning allows engineers to identify and eliminate design errors early in the process, decreasing the development and validation time, while reducing risk and potential damage.

Explore Products

Production Integration

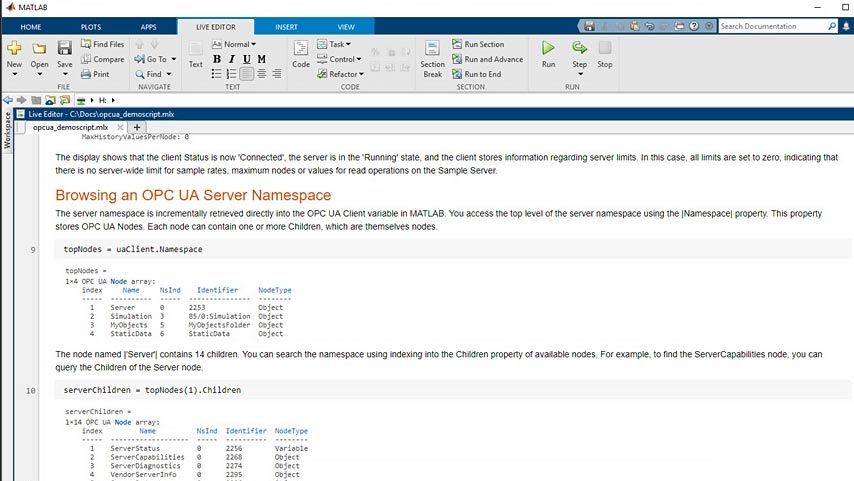

MATLAB and Simulink algorithms can be deployed in production on devices at the field level (edge), supervisory and control level, or enterprise level (server or cloud IT).

MATLAB and Simulink can communicate through a wide range of busses and protocols, such as:

- OPC UA

- Ethernet TCP or UDP

- EtherCAT

- CAN

- Serial (e.g., RS232 or RS485)

- Modbus

- GPIB

Engineers can also integrate MATLAB and Simulink with software, such as the AVEVA™ PI System™.